Botlenick Araes Of Vertical Roller Mill

مجال التطبيق

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

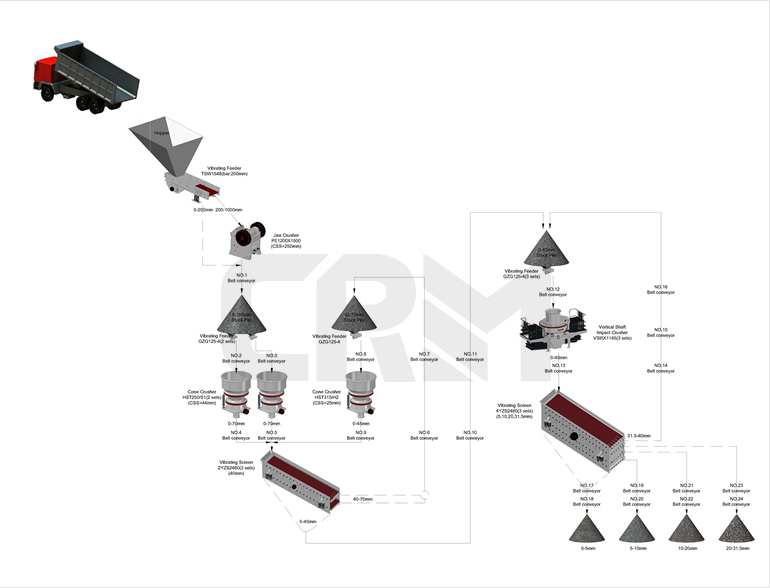

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries. In this study, the discrete element method

sbm/sbm botlenick araes of vertical roller mill.md at master

sbm botlenick araes of vertical roller millaraes botlenick araes of vertical roller mill araes botlenick araes of vertical roller mill Botlenick Araes Of Vertical Roller Mill

Review on vertical roller mill in cement industry its

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials. With the grinding capacity of a vertical roller

VERTICAL ROLLER MILLS A holistic VRM approach

2022年4月4日 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and

Modelling of pilot scale vertical roller mill operated in

2019年7月16日 Pilot scale grinding tests were performed for various materials by a mobile unit for modelling studies. Vertical roller mill was separated into the two section as

Design parameters of vertical roller mill Download Table

For grinding cement, two types of mills are used - ball and roller. Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials.

botlenick araes of vertical roller mill

Vertical Roller Mill This Vertical Roller Mill is used to mill the rude cement material and clinker cement and other raw materials for building, chemical and ceramic industry, with

Modeling and simulation of vertical roller mill using

In this research work, the application of population balance model for simulation of a VRM in a cement clinker grinding circuit was investigated. The residence time distribution (RTD)

Increase productivity of vertical roller mill using seven QC

2021年1月1日 In recent years vertical roller mill (VRM) has proved to be a popular choice for finished cement grinding due to low power consumption but it is also very sensitive to

The Evolution of Cement Vertical Roller Mills - Medium

3 min read May 13, 2024--Listen

Vertical roller mills FLSmidth Cement

OK™ Raw and Cement Mill. Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement ...

Vertical Roller Mill Magotteaux

Vertical roller mills have numerous applications in many different industries.Although they are widely used in the cement sector, for example, you are just as likely to find a vertical roller mill being used to handle ores in mining processing plants.There again, vertical roller mills also have uses within the context of power stations where they are primarily used to

Study on Particle Characteristics of Cement by Vertical Roller Mill ...

2013年5月1日 The particle characters and their physical properties of vertical roller mill finish grinding cements were studied in this paper. The difference with roller press-ball mill combined grinding products was also analysis. The results were shown that the particle size of the vertical roller mill finish grinding cements was more evenly distributed at the

Vertical roller mills: The new leader in grinding technology

2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the vertical-roller-mill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted. This is considered a resistance to change

Parts of Vertical Roller Mill - INFINITY FOR CEMENT

Vertical Roller mills. Vertical Roller mills Main parts of a vertical roller mill Mill body feed Hydraulic system Nozzle and retention ring mill body seperator Vertical roller mill: frame type Polysius: Polroll Gbr. Pfeiffer: MPS Vertical roller mill: rocker arm type Loesche: LM Kobelco: OK Processes inside a vertical roller mill Grinding

Triple Roller Mill: Principle, Construction, Diagram, Working,

2023年7月19日 Triple Roller Mill. The triple roller mill contains three rollers made from hard abrasion-resistant material. The rollers are separated by a minimum distance of 0.05 mm, and a maximum up to 0.3 mm. These rollers are arranged close to each other, ensuring optimal efficiency. Additionally, they are set to rotate at different speeds.

Finite Element Analysis for Rocker Arms of Vertical Roller Mill

2011年5月1日 Based on illuminating the structure,working principle and force analysis of vertical roller mill, the finite element analysis of rocker arms is carried out on ANSYS Workbench (AWE) platform. First of all, the structure of rocker arms and grinding roll components are simplified,then the three-dimensional entity model and meshing model

Dynamic Modeling and Vibration Analysis of a Vertical Roller Mill

2011年9月23日 Abstract. This paper studies mathematical model of a Vertical Roller Mill (VRM). VRMs are widely used in cement, chemical, coal and electricity industries to reduce particle sizes of raw materials ...

Raymond® Roller Mill air-swept vertical ring-roll - Schenck

The Raymond ® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce ...

Vertical Roller Mill (VRM) - INFINITY FOR

2018 Target Operating Hours in Cement industry S.No. Department Operating hrs/Day 1. Mines* 10 2. Crusher* 10 3. Raw Mill (Ball mill, VRM) 21 Raw mill (Roller press) 20 4. Coal mill (Ball mill, VRM) 21 5. Kiln 24 6.

Atlas Vertical Roller Mill - NETZSCH Grinding Dispersing

-ecut-ec NE1ZSCH Proven Excellence, Atlas Vertical Roller Mill for Fine Products MINERALS MINING a Business Field of NETZSCH Grinding Disperse. Open the catalog to page 1. Atlas The ATLAS is a roller air-swept mill designed for continuous operation with minimum maintenance. The fundamental difference between the ATLAS

Latest Installations And Developments Of Loesche Vertical - Roller ...

2012年9月1日 The paper is giving an overview about successful operating Loesche Vertical ? Roller ? Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow- and Overflow-Mode. Some of these benefits are optimised energy efficiency of the grinding - classifying - circuits, increased

Numerical Investigation of Vertical Roller Mill Operation

2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics. The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM. This study investigated the effect of table speed (mill speed), roller and table gap, dam ring

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The

What is a vertical roller mill (VRM)? A Comprehensive Guide

2023年10月3日 Grinding Rollers: Grinding roller is the main part for crushing and grinding materials. The grinding roller is composed of cast steel roller sleeve, forging shaft and wear-resistant surfacing bushing. The grinding roller is installed on the rocker arm of the cement vertical roller mill, under the action of external force, it is pressed tightly on the material of

How to Maintain the Constant Temperature of Vertical Roller Mill

1.The bearing of grinding roller and bearing should be added oil regularly. 2.If the vertical roller mill is in bad quality, the temperature will also rise. 3.The room temperature of cement vertical roller mill can not over 70℃, if the temperature of bearing is over-heated, we should demount it and clear the bearing and bearing room.

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the ...

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت